Handling Pharmaceutical Grade 134A Propellant and Finding the Correct Equipment for the Application.

Customer

Hi RefTec,

I am a consulting engineer in Raleigh, NC. I have a pharmaceutical client in Zebulon, NC that utilizes pharmaceutical grade 134a propellant as a motive for the drug within their inhalers. The propellant is almost identical to traditional R134a, just without the oils and other additives.

Currently, their SOP releases some of this propellant to the atmosphere and they are interested in reclaiming this. I think that RefTec has a multitude of equipment to help with this. Am I able to set up a meeting to discuss more in depth? I can also respond with more lengthy, detailed emails describing my situation. Please let me know if you can help.

RefTec

Good Day Client,

How much to they have at one time that they are releasing or wanting to recover ?

Is this all in a Vapor form ?

Customer

Thanks for inquiring. The biggest issue is the propellant

that is lost to atmosphere when breaking the connections on the delivery truck.

The site receives around 30 deliveries per year and when the offload is

complete there is always some “heel” within the tank (essentially, they can’t

get all the propellant out). Therefore, when the connection is broken there is

still propellant within the hoses (liquid and vapor connection) that currently

is bled off to atmosphere so that the hose is free from propellant and can be

connected to the next full tanker.

The current piping set-up uses short steel spool pieces (2” on liquid & 1-1/2” on vapor) that are only a few feet long to connect to the delivery tank. The hose is isolated upstream and downstream and therefore the only propellant loss that occurs is through the spool pieces, which I estimated at 10 lb. The issue with this existing set-up is the hoses stay full of propellant and therefore are heavy and a pain for maintenance. The hoses are 20 ft long and one is full of liquid propellant which I estimate to be well over 50 lb.

Existing liquid hose is filled with propellant during changeover, making the switch difficult on the maintenance team.

Existing P&ID. Currently just the spool pieces are vented, but that causes the hoses to be heavy. The client would like to eliminate the spool pieces and be able to reclaim the propellant within the hose.

So, the client would like to eliminate the spool piece and connect the hose directly to the tanker. To do this the propellant within the hose would need to be evacuated and reclaimed before the connection is broken. I estimated 50 lb of recovery per offload. The propellant would be in liquid form. The site currently has a Lite Evac HP recovery skid that I have seen used by them before. I believe the Lite Evac HP skid only wants vapor at the inlet of the compressor and therefore a flash/break tank (propane sized tank) was used as a “buffer” to ensure that vapor entered the compressor … is this a common practice?

Here is the proposed P&ID at the moment. The idea is to reclaim the propellant within the hose prior to the connection being broken.

My plan was to utilize the Handivac Recovery Unit with an ASME-120-075-HP tank. The questions that I have are:

- Why

is the Handivac able to handle liquid, but it appears the Lite Evac HP

recovery skid only likes vapor? Does the Handivac have an orifice or some

other item that ensures the compressor only sees vapor?

- Is

there any concern that the ASME-120-075-HP would be located outside? The

placement will be in the shade, and I think a cover is a good idea. How

does the life expectancy change when it is located outside?

- I

am assuming that it is okay to intermittently connect to this tank and

reclaim propellant into it or does it need to be emptied after every use?

The idea was to have a storage tank of reclaimed propellant on site and

only need to have a third-party reclaim company come in once or twice a

year to empty the tank.

- This

site is very particular about pressure relief devices. Are you able to

provide compliance documentation stating that the vessel’s relief valves

are sized appropriately.

- The

site has a “waste tank” on site that excess propellant mixed with API

(active pharma ingredient) is pumped to from the production suite. Instead

of having a dedicated ASME-120-075-HP vessel, does it make sense to

connect the Handivac to the waste tank? My concerns are:

- The

distance from the offloading station to the waste tank is very long (~150

ft). I am concerned that the far distance will increase the reclaim time

and also increase the power consumption of the compressor.

- The waste tank is only rated for 160 PSIG. Is there a concern that connecting the Handivac will over pressurize the vessel? Assuming there is enough room to accommodate the propellant, I do not foresee the tank being overpressureized because the pressure in the waste tank is maintained by the propellant which is based on ambient temperature.

RefTec

Client,

Does the Propellant not get put into a storage tank on each fill , or are they just charging the lines

Definitely need to have the hoses empty of all propellant

Client

Yes, the propellant is offloaded onto larger storage tanks that then have their own pumps to pump into the production building. After each offload they close off the off-load skid. Here is a bigger picture of the P&ID. Were you thinking about possibly reclaiming into the storage tanks? That is feasible, as long as we can prove that the propellant will not be compromised by oils or any other unwanted additives that might be incurred through the recovery equipment. Note that these storage tanks are ~100 ft away from the off load skid.

Let me start working on a proposal for you , it may take a week

Do you ever have a moisture issue building up in lines or storage tanks ?

Client

I got some direction from the client. They prefer to

route the reclaimed propellant to a dedicated knock-out tank in lieu of

connecting it into the storage vessel. The knock-out would then be emptied on a

yearly basis.

The site currently has a Lite Evac Recovery Unit. Does this piece of equipment have an IOM? I cannot find one online.

The piping set-up I have seen before is shown below. I am wondering if the intermediate propane size break tank is necessary to ensure vapor flow to the recovery unit or if the recovery unit is able to accept liquid?

Is the unit a 4 wheel or Stand up model ?

The drawing is correct , You need the tank before the unit incase during vapor recovery -liquid shows up as the unit can not take direct liquid

Client

That makes sense. I believe the unit is a

4-wheel. I need to discuss with the techs to determine if that is acceptable or

if something more mobile is necessary.

Out of curiosity, what makes this handivac able to handle

liquid, but the Lite Evac can’t?

Attached is the OEM for the unit . As for the reason

why , The Lite evac has an open drive compressor , they can not take liquid

only vapor. That is why they do push pull for liquid . The handivac has

(2) oil less compressors , they are lubed by the oil in refrigerant. If the

refrigerant is virgin or only vapor the unit can only run for 40-45min

until need shut down to cool down. As it will dry out the compressors & causing

damage .

That is why I was thinking a Corken D91 or D191 compressor , They handle both liquid and vapor as well has seal crank case so no oil is lost

Client

Brian – Are you able to give me the recovery rates for 134a vapor for these selections?

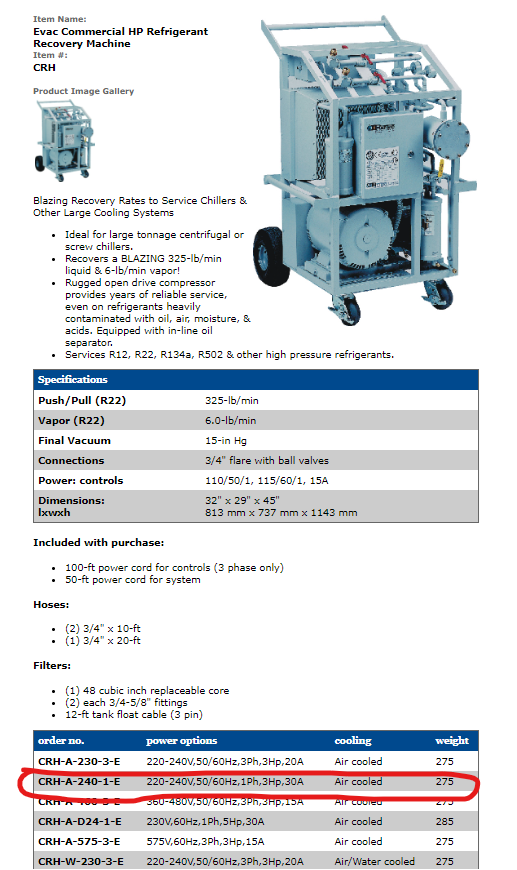

See below rates – for Both Evac & Allvac Unit

Push/Pull Rates (liquid) (R22) 325-lbs/min (R134a) 307-lbs/min (R410a) 295-lbs/min

Vapor

Rates

(R22) 6.0-lbs/min

(R134a) 5.11-lbs/min (R410a)

4.95-lbs/min32

NOTE: Nether unit can take direct liquid

Comments

Post a Comment